*Introduction of IC engine components.

An internal combustion (IC) engine is a type of heat engine that Generates power by burning fuel within the engine itself. It is Commonly used in vehicles, such as cars, motorcycles, and boats, as Well as in generators and other equipment. IC engines work by burning a fuel-air mixture inside the engine, which Produces a high-pressure gas that expands and pushes a piston. This Piston is connected to a crankshaft, which converts the linear motion Of the piston into rotational motion that can be used to power a Vehicle or generator. There are two main types of IC engines: spark ignition engines and Compression ignition engines. Spark ignition engines, also known as Gasoline engines, use a spark plug to ignite the fuel-air mixture. Compression ignition engines, also known as diesel engines, compress The air in the engine so much that it heats up and ignites the fuel Without the need for a spark plug.

*Function and construction of these components.

1] Cylinder block

The cylinder block, also known as the engine block, is the core Component of an internal combustion engine. It is usually made of Cast iron or aluminum and contains the cylinders, crankshaft, and Other vital components. The cylinders are where the fuel-air mixture is Burned and converted into mechanical energy. The block also houses The pistons, connecting rods, and bearings that help convert the Energy into rotational motion. The block is typically designed with Cooling passages to help dissipate the heat generated by the Combustion process. The construction and layout of the block can vary Depending on the engine type and design, such as inline, V-shaped, or Flat. Proper maintenance and care of the cylinder block is essential for The longevity and performance of the engine.

2] Cylinder head

The cylinder head is a vital component of an internal combustion Engine, as it covers and seals the top of the cylinders, forming the Combustion chamber where the fuel-air mixture is ignited. The cylinder Head is usually made of cast iron or aluminum and is bolted to the top Of the engine block. It contains the intake and exhaust valves, which Open and close to allow the fuel-air mixture to enter the cylinder and The exhaust gases to exit. The cylinder head also houses the spark lugs or fuel injectors, depending on the engine type. The head is Designed with cooling passages to help dissipate the heat generated By the combustion process. The cylinder head is usually the most Complex and expensive part of the engine, and proper maintenance And care are essential for reliable engine performance.

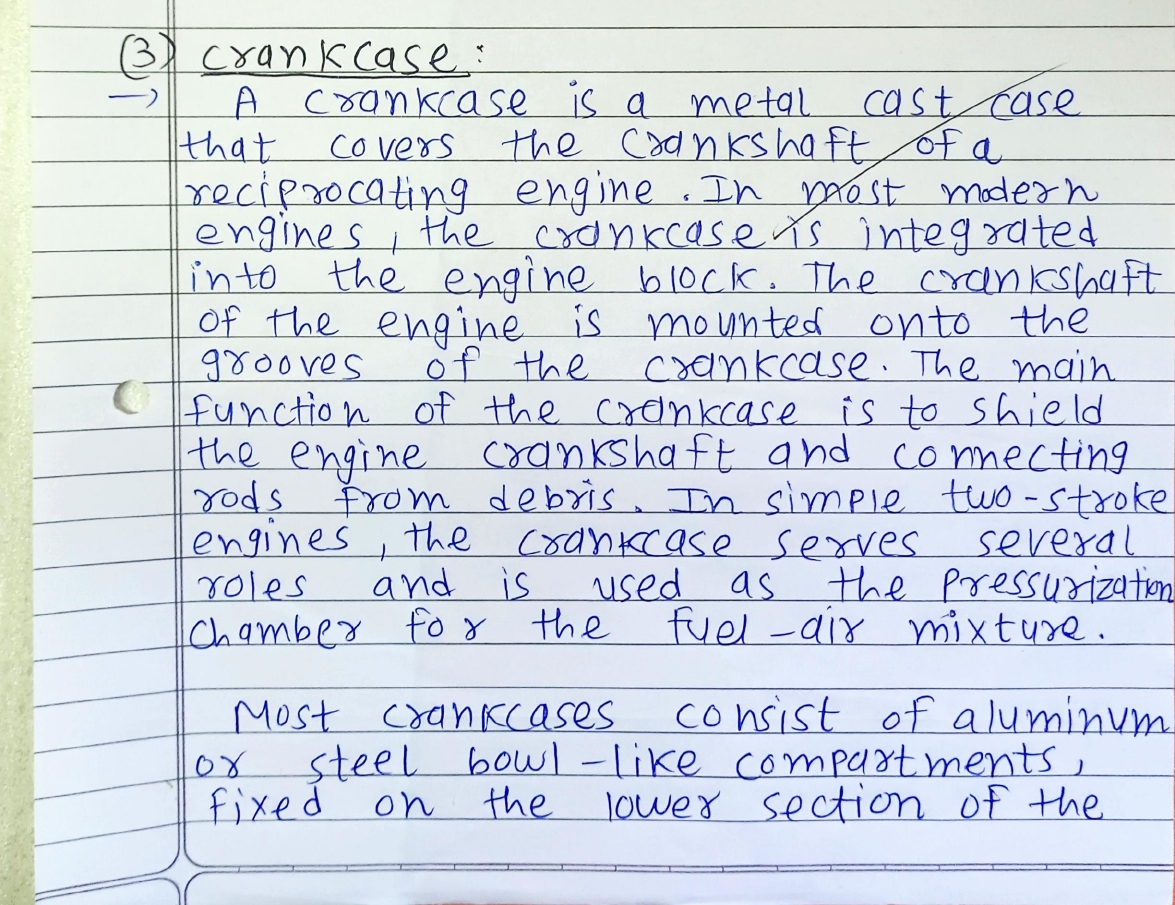

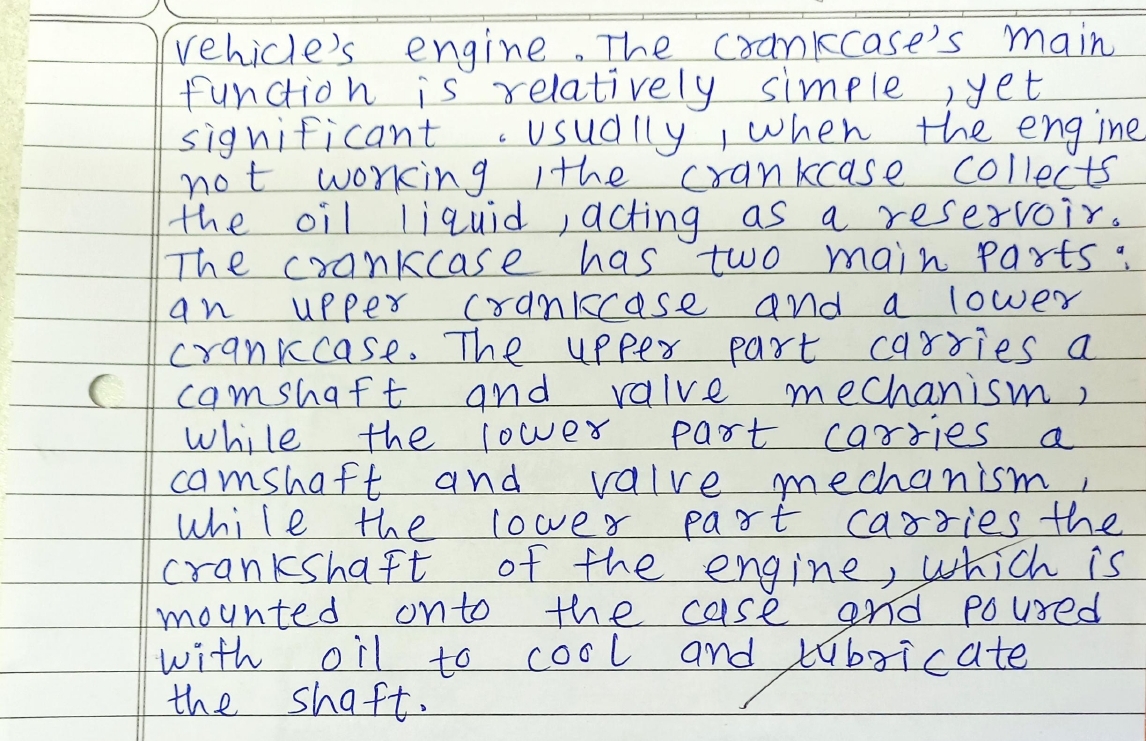

3] Crankcase

4] Piston

The piston is a cylindrical component that moves up and down Inside the cylinder bore. Its primary function is to convert the pressure Generated by the combustion of fuel into mechanical force that can be Transmitted to the crankshaft. The piston is usually made of cast Aluminum alloy and is precision machined to exacting tolerances. It is Designed with a crown on the top that forms the combustion Chamber, and it has a skirt that fits closely to the cylinder walls to Prevent gases from escaping.

5] Piston rings

The piston rings are thin metal rings that fit tightly Around the circumference of the piston. Their primary function is to Seal the combustion chamber and prevent gases from escaping past The piston into the crankcase. The piston rings also help to transfer Heat from the piston to the cylinder walls, and they provide lubrication To the piston as it moves up and down. The piston rings are usually Made of cast iron or steel, and they are designed with a beveled edge That allows them to expand and contract as the engine heats up and Cools down.

6] Piston pin

The piston pin, also known as the wrist pin, is a cylindrical Pin that connects the piston to the connecting rod. Its primary Function is to allow the piston to pivot and move freely as it travels up And down the cylinder bore. The piston pin is usually made of Hardened steel, and it is precision machined to fit tightly in the piston And connecting rod.

7] Connecting rod

The connecting rod is a component that connects the piston to the Crankshaft in an internal combustion engine. It is made of forged steel, Designed with bearings at both ends and is critical for reliable engine Performance. Lubrication is essential to reduce friction and wear, and The rod should be periodically checked for signs of wear or damage. High-performance engines may use lightweight materials such as Titanium for connecting rods to improve performance.

8] Crankshaft

The crankshaft is a vital component of an internal combustion engine, As it converts the reciprocating motion of the pistons into rotational Motion, which drives the wheels of the vehicle. The crankshaft is Usually made of forged steel and is precision machined to exacting Tolerances. The crankshaft is designed with multiple bearings that Support it within the engine block and help reduce friction and wear. The bearings are lubricated by oil that is circulated through the Engine. The crankshaft is typically designed with counterweights that Help balance the rotating mass and reduce vibration. The design and Construction of the crankshaft can vary depending on the engine type And size, but it is always a critical component that must be properly Maintained and cared for to ensure reliable engine performance.

9] Flywheel

The flywheel and crankshaft are important components of an internal Combustion engine. The flywheel is attached to the crankshaft and serves as a reservoir of Rotational energy, helping to smooth out the power delivery from the Engine. The flywheel also helps to maintain the engine’s idle speed And reduces vibration. The flywheel is oftenMade of cast iron or steel and can be either solid or dual-mass. Proper Balancing of both the flywheel and crankshaft is essential for smooth Engine operation and longevity

10] Camshaft

11] Valve and valve mechanism

Valves control the flow of air, fuel, and exhaust gases in internal Combustion engines. The valve mechanism is responsible for opening And closing valves at the right time. Cam-driven systems are common, With a camshaft rotating at half the speed of the crankshaft to push Against tappets, push rods, rocker arms, and valve stems. Valve timing Is critical for engine performance and can be set using adjustable cam Sprockets or by changing the position of the camshaft. Modern Engines use variable valve timing (VVT) to improve fuel efficiency and Power output.

12] Rocker arm

13] Air filter

An air filter removes impurities from the air before it enters an engine To protect it from damage. It consists of a filter element and housing, And there are different types available including paper filters, high- Flow performance filters, and reusable filters. Regular maintenance and Replacement is necessary to prevent decreased engine performance And fuel efficiency. Some filters can also reduce emissions by trapping Harmful pollutants.

14] Oil filter

An oil filter is a component in an engine’s lubrication system that Filters out impurities from the oil to protect the engine from wear and Damage. It consists of a filter element and housing, and regular Maintenance and replacement is necessary to prevent decreased Engine performance and damage. There are various types of oil filters Available, including performance and extended-life filters. Some oil Filters can also reduce emissions by trapping harmful pollutants.

15] Spark plug

A spark plug is an electrical component that ignites the fuel mixture in An internal combustion engine. It consists of a metal shell, an insulated Central electrode, and a ground electrode. When high voltage is Delivered to the central electrode, it creates a spark that ignites the Fuel mixture, starting the combustion process. Spark plugs must be Maintained properly and replaced regularly to ensure optimal engine Performance.

16] Carburetor

A carburetor is a device used in older internal combustion engines to Mix fuel and air in the correct ratio before it is delivered to the engine For combustion. It works by using a venturi to create a vacuum that Draws air into the engine through a series of calibrated jets and Passages. Fuel is then added through the fuel jets and mixed with the Air to form a combustible mixture. The carburetor also includes a Throttle valve to control the amount of air and fuel delivered to the Engine. However, modern engines have replaced carburetors with fuel Injection systems due to their ability to provide more precise fuel Delivery and better engine performance.

//livingshedhowever.com/c873624a3005cc84a13a6554833882ad/invoke.js17] Fuel injector

A fuel injector is a component in the fuel delivery system of an internal Combustion engine that injects fuel into the combustion chamber. The Injector works by receiving a signal from the engine control unit (ECU) And using a solenoid to open a valve and allow pressurized fuel to Spray into the engine. The amount of fuel injected is controlled by the ECU, which calculates the engine’s needs based on factors such as air Flow and throttle position. Fuel injectors can help improve engine Performance and fuel efficiency by providing more precise control Over fuel delivery. They can also reduce emissions by ensuring that Fuel is burned more completely. However, they require regular Maintenance to prevent clogging and ensure proper operation.

18] Introduction of engine materials

The choice of materials for an engine is important as it can affect its Performance, durability, and cost. Here are some common materials Used in engine construction :

- Cast Iron: Cast iron is a popular material for engine blocks and cylinder Heads due to its high strength, durability, and ability to dissipate heat.

It is also heavy and can be prone to cracking under stress.

- Aluminum Alloy: Aluminum alloy is lighter than cast iron and is Commonly used in engine blocks, cylinder heads, and pistons. It is Easier to machine than cast iron and has better thermal conductivity, But it is not as strong and can wear out faster.

- Steel: Steel is used in various engine components such as connecting Rods, crankshafts, and valve springs. It is strong and durable but also Heavy.

- Titanium: Titanium is a lightweight and strong material that is used in High-performance engines. It is commonly used in valve springs and Connecting rods.

- Ceramic: Ceramic is used in engine components such as bearings, Valve coatings, and exhaust systems. It is known for its high heat Resistance and low friction, but it is also expensive.

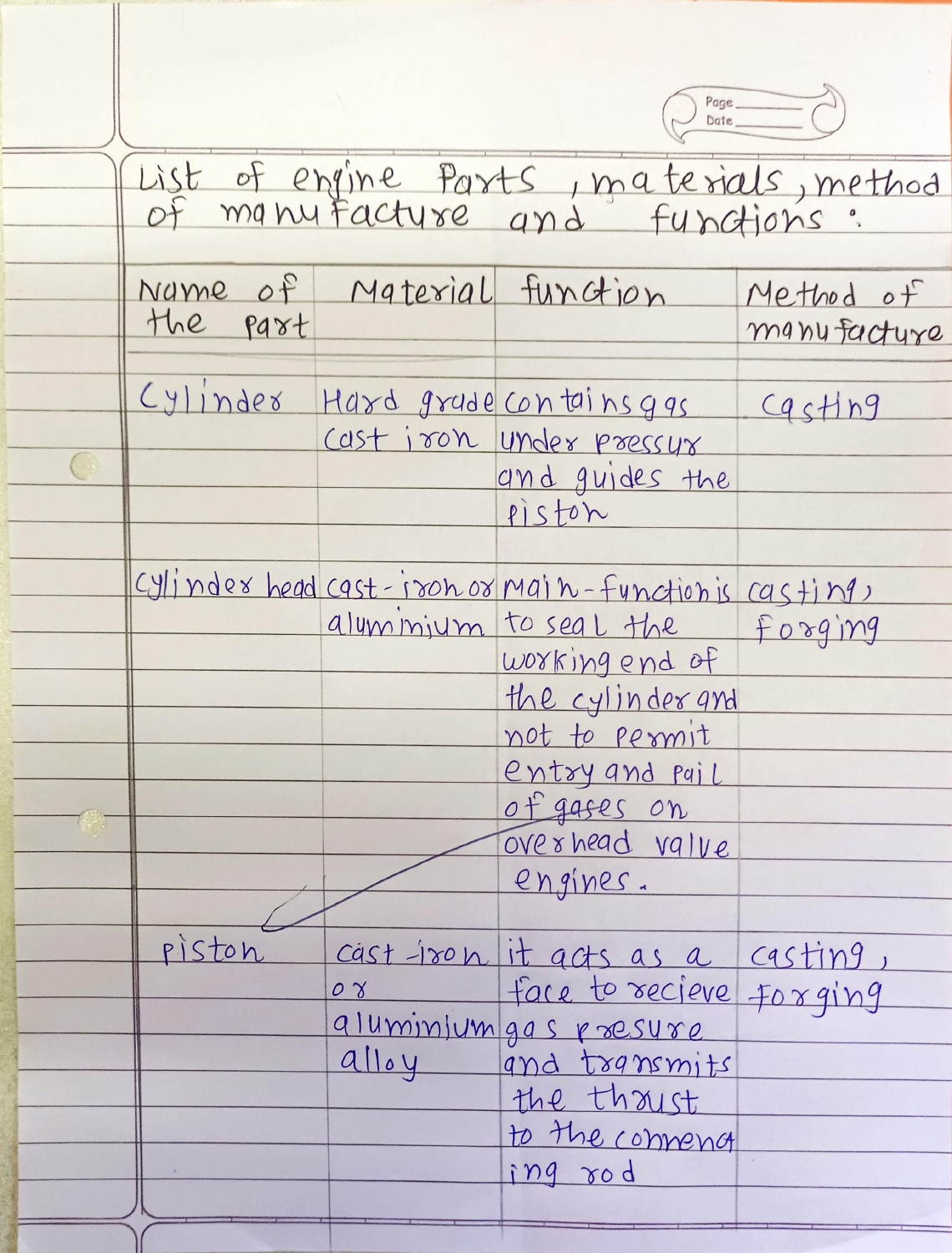

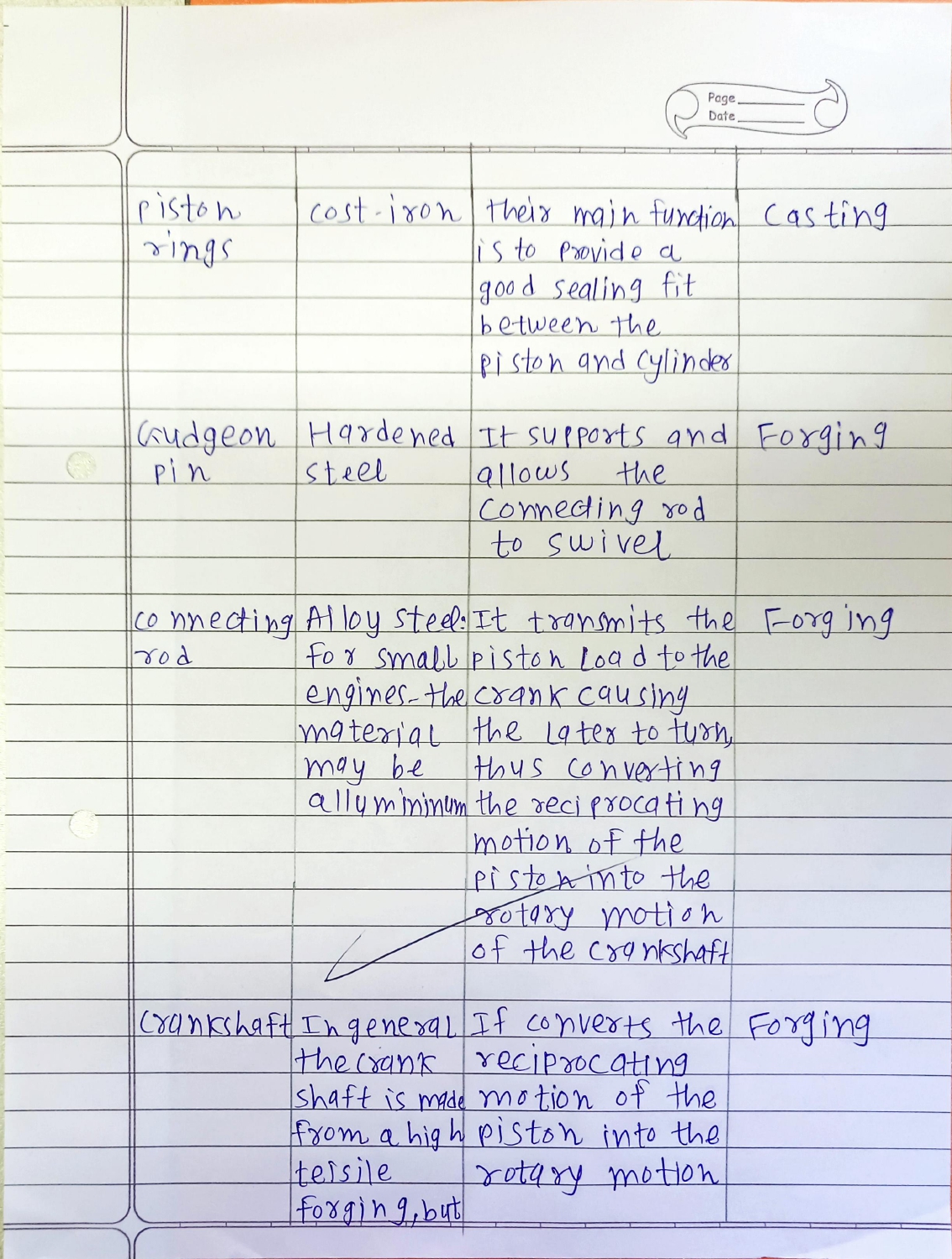

List of engine parts, Materials , method of manufacture and functions.